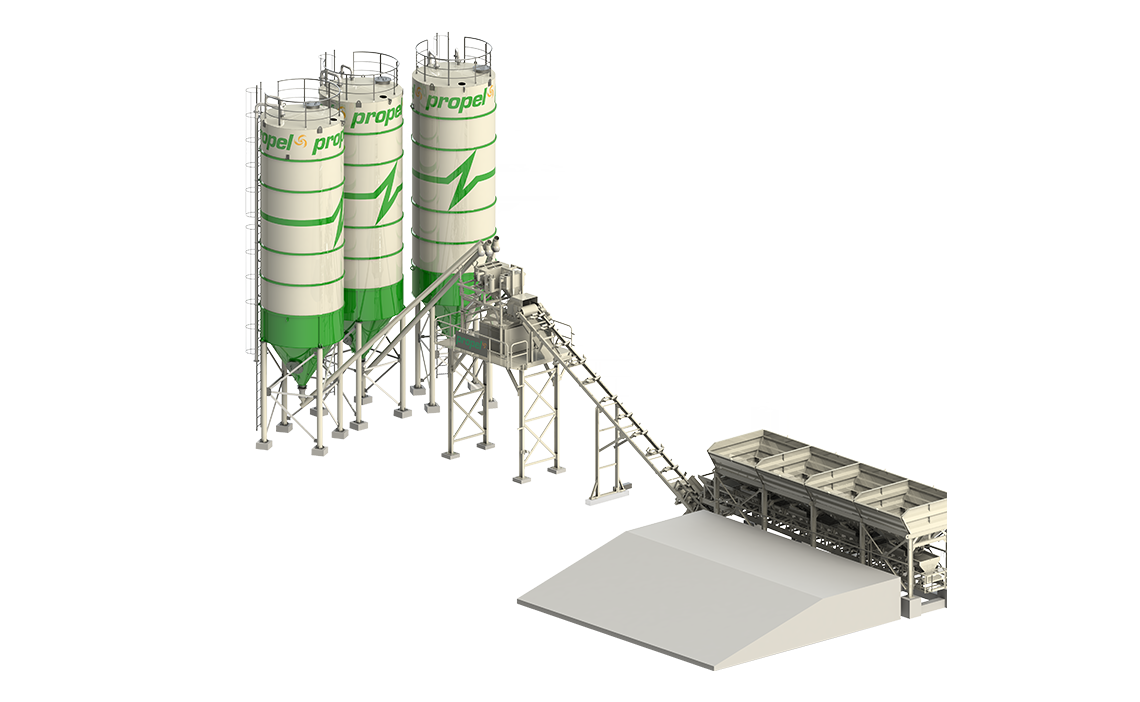

CONCRETE BATCHING SOLUTIONS

PRO SERIES 30 TCI | 45 TCI | 60 TCI | 75 TCI | 90 TCI | 120 TCI

The Pro-Series of Propel Batching plant is sure to meet all your business requirements. Our team will provide end-to-end custom-made solutions!

Know Better

Propel Industries provides innovative, technologically-sound and cost-effective solutions to the crushing and screening industry. We are the strategic business division of the 62-year-old Coimbatore-based AV Group. We provide a comprehensive range of products with high reliability. Enhanced performance and versatile applications at optimal costs has made us the market leaders.

Indigenously developed for the concrete industry

Customised solutions for your needs

WATCH VIDEO

TECHNICAL DATA

| DESCRIPTION | UNITS | PRO 30 TSM / TCI | PRO 45 TCI | PRO 60 TCI | PRO 75 TCI | PRO 90 TCI | PRO 120 TCI | |

|---|---|---|---|---|---|---|---|---|

| Basic Information | ||||||||

| Output | m3/h | 30 | 45 | 60 | 75 | 90 | 120 | |

| Space Required | m | 12x3* | 30x4* / 25x20* | 30x4* / 25x20* | 30x4* / 25x20* | 30x4* / 25x20* | 30x4* / 25x20* | |

| Concrete Discharge Height | m | 4 | 4.1 | 4.1 | 4.1 | 4.1 | 4.1 | |

| Mixer System | ||||||||

| Mixer Type | Twin Shaft / Planetary Mixer | Twin Shaft | ||||||

| Mix Volume (Wet) | m3 | 0.5 | 0.75 | 1 | 1.25 | 2 | 3 | |

| Aggregate Management | ||||||||

| Bin Type | Compartment / Inline | Inline | ||||||

| Number of Bins | 4 | 4 | 4~ | |||||

| Total Capacity | m3 | 20 | 30 | 40# | 80# | 100# | ||

| Ramp Height & | m | 1.2 | 1.2 | 1.4 | 1.4 | 1.8 | 1.8 | |

| Aggregate Weighing | Belt Conveyor | |||||||

| Aggregate Transfer to Mixer | Skip Bucket | Inclined Belt Conveyor | ||||||

| Max. Weighing Capacity | ||||||||

| Aggregate | kg | 1250 | 1875 | 2500 | 3150 | 5500 | 7500 | |

| Cement / Filler | kg | 350 | 525 | 700 | 700 | 1350 | 1800 | |

| Water | kg | 150 | 250 | 400 | 400 | 680 | 900 | |

| Additive | kg | 12 | 12 | 12 | 12 | 2 x 12 | 2 x 12 | |

| Air Compressor | kW(hp) | 3.7 (5) | 3.7 (5) | 5.5 (7.5) | 5.5 (7.5) | 7.5 (10) | 7.5 (10) | |

| Max. Pressure | Bar | 12 | 12 | 9 | 9 | 9 | 9 | |

| Space Required | Lit | 220 | 220 | 220 | 220 | 400 | 400 | |

| Control System | Fully automatic SCADA based PLC control panel with Computer and printer | |||||||

| Electrical Load | ||||||||

| Total Connected Load | kW (hp) 4 | 56 (75) | 63 (82) | 87 (117) | 99 (133) | 146 (196) | 202 (271) | |

| Genset Suggestion^ | kVa | 62.5 | 82.5 | 125 | 160 | 200 | 250 | |

screw conveyors of various sizes for Cement / Fly Ash / GGBS / Micro silica available

* standard plant foot print without silo

~ can be increased upto 6

# can be increased from 60 to 150 m3

& calculated for standard BHL

$ with 1 standard screw conveyor

^ Only for plant operation (Blower and Return filters not considered).may vary due to DGcondition,efficiency etc.